Instant Quoting for Custom Part Manufacturing: Radii InstantQuote

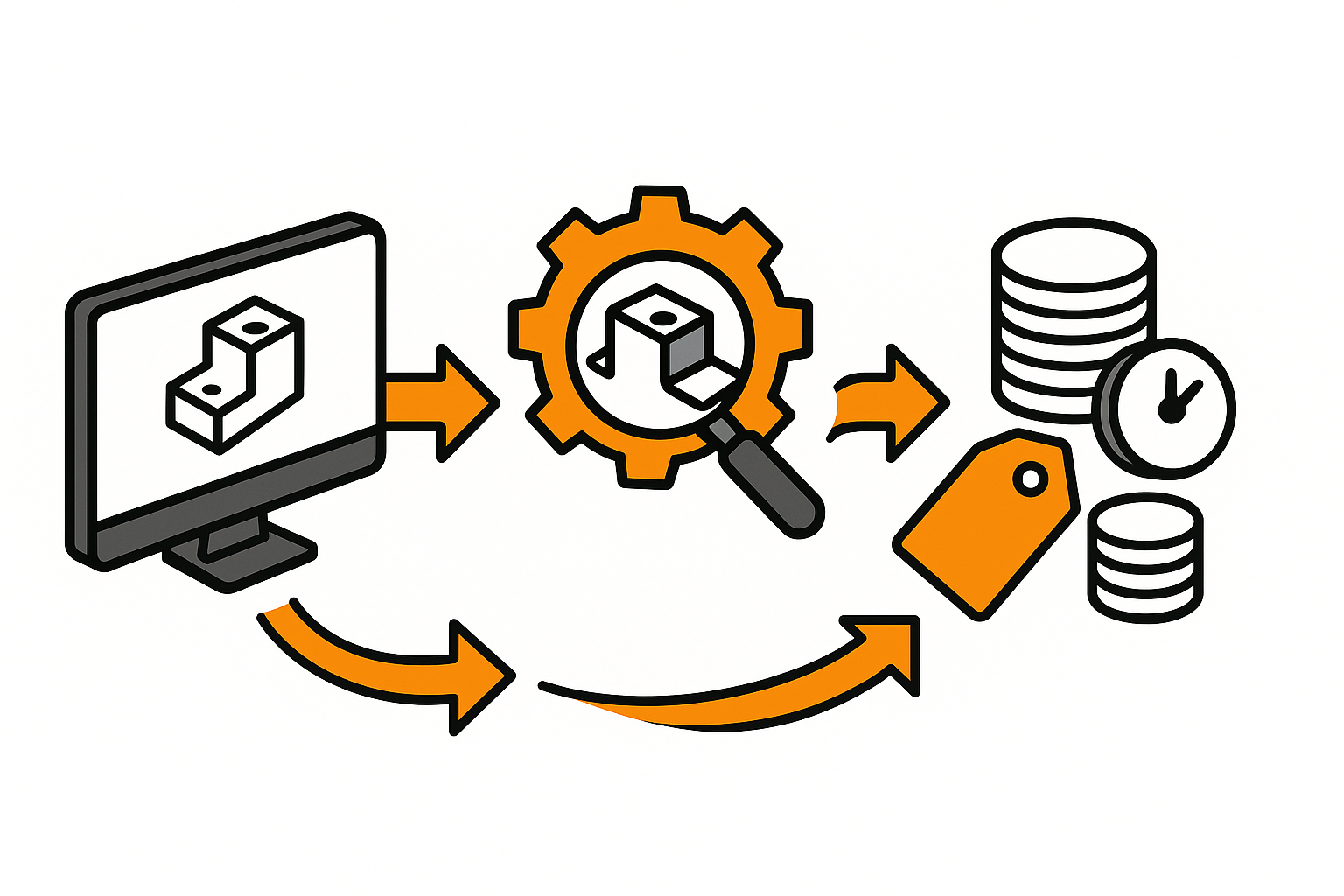

Instant quoting for custom parts lets you get price and lead time in seconds from a CAD file, with automated DFM analysis to prevent issues before production.

Instant Quoting for Custom Part Manufacturing: Radii InstantQuote

Instant quoting for custom part manufacturing reduces response time from weeks to seconds through automated CAD file analysis. Platforms like Radii InstantQuote process complex geometries and deliver accurate real-time pricing, enabling automotive and aerospace companies to iterate designs faster and reach the market sooner.

Summary

• Game-changing speed: Traditional quotes take days or weeks; digital platforms deliver results in seconds to minutes

• Integrated DFM analysis: Automatic manufacturability evaluation that detects design issues before production, reducing errors starting at the quoting stage

• Nearshoring advantage: Mexico is positioning itself as a strategic hub with more than 100 announced project and $30 billion in investment

• Ultra-fast deliveries: CNC parts available in as little as 3 days, with urgent options in 24 hours

• Robust network: Radii connects more than 200 certified suppliers with access to 5,000 CNC machines

• Quality guaranteed: Processes aligned with ISO 9001:2015 and rigorous audits at every production stage

Imagine getting the exact price for your CNC part in seconds, not weeks. Instant quoting is transforming manufacturing by eliminating the traditional wait and accelerating the time-to-market for automotive, aerospace, and medical device companies. In an environment where nearshoring in Mexico is expected to increase exports by more than $500 billion by 2030, having digital tools that streamline the supply chain is no longer optional—it’s strategic.

In this article, we explain what instant quoting is, how Radii InstantQuote works, and why it outperforms traditional manual methods.

Why does instant quoting accelerate the industry?

Instant quoting is the price and lead time calculated automatically from your part’s CAD file. Platforms like Radii InstantQuote combine big-data algorithms with process parameters to show you the true cost—without emails or calls.

Why does speed matter so much at this stage?

-

Errors that start at quoting: “Most errors that affect production can be traced back to a common source: the quoting stage” (Lantek).

-

End-to-end platform: Radii centralizes more than 200 suppliers in a single platform that manages production, quality, and logistics—optimizing your supply chain and ensuring high-quality parts.

-

Competitive advantage: Instant quote generators help save time in the quoting phase and get part pricing immediately.

Cutting wait times from weeks to seconds means iterating faster, identifying design issues before production, and reaching the market ahead of the competition.

Section conclusion: Instant quoting removes administrative bottlenecks and turns speed into a real competitive advantage.

How does Radii InstantQuote work end to end?

The digital flow of Radii InstantQuote can be summarized in three steps:

| Step | What happens | Benefit |

|---|---|---|

| 1. Upload your CAD | You upload your STEP, IGES, or similar file | No emails, no waiting |

| 2. Automated DFM analysis | The system evaluates geometry, tolerances, and materials | Detects risks before production |

| 3. Price and lead time in seconds | You receive a quote with material and finishing options | Immediate decision-making |

Integrated DFM analysis

Automated design analysis takes your CAD and typically provides insight within a couple of hours on whether your design is manufacturable. This allows you to adjust problematic geometries before investing in production.

Automation that saves time

Manufacturing quoting software speeds up the process and automates complex calculations, reducing reliance on technical experts for every quote.

Manufacturing precision

Radii offers 3-, 4-, and 5-axis CNC manufacturing with tolerances of ±0.005 mm, ensuring the price you see matches the part you receive.

InstantQuote vs. manual quoting: which wins on time and cost?

The difference between traditional quoting and using a digital platform is dramatic:

| Criterion | Manual quoting | Instant quoting |

|---|---|---|

| Response time | Days or weeks | Seconds to minutes |

| CNC part delivery | Varies | As fast as 3 days |

| Urgent machined parts | Weeks | As fast as 1 day |

| DFM analysis | Requires engineers | Automated |

Speed in rapid prototyping

Rapid prototyping helps engineers and designers make quick and frequent changes to their designs. With 3D printing, lead times range from 1 to 3 business days.

Digital competitors

Digital manufacturing platforms offer a one-day rush service for less complex parts, and most of their quotes have a 5-day lead time. Radii combines this speed with the nearshoring advantage in Mexico and a network of more than 5,000 machines.

The hidden costs of waiting

Every day of delay in receiving a quote represents an opportunity cost. As the saying goes: “Time is money—and your time is especially valuable.”

How does instant quoting impact supply chains and nearshoring?

Instant quoting doesn’t just speed up purchasing—it transforms the entire supply chain.

Mexico as a strategic hub

In 2023, Mexico became the largest supplier of goods to the United States, a position China held since 2007.

This nearshoring trend benefits companies looking for:

- Reduced transit times: Fast ground logistics to the U.S.

- Time-zone alignment: Real-time communication with North American customers.

- Cost competitiveness: Skilled labor at lower cost than Asia.

Growing investment

More than 100 nearshoring projects have been announced in Mexico, with an estimated total investment of more than $30 billion. The industries benefiting the most are electronics and automotive.

Resilience over cost reduction

More than 50% of supply chain leaders plan to increase their nearshoring operations, prioritizing resilience over simple cost reduction.

Section conclusion: Instant quoting, combined with Mexico’s strategic location, delivers speed, resilience, and competitiveness in one package.

Quality assurance: from ISO 9001 to digital supplier audits

Speed without quality is useless. That’s why Radii InstantQuote integrates rigorous quality processes.

ISO 9001 fundamentals

ISO 9001:2015 is an international standard that specifies the requirements for a quality management system. It promotes a process approach and risk-based thinking to ensure each part meets standards.

Supplier audits

A supplier audit is a “formalized system for evaluating the reliability and competence of suppliers and vendors to provide a quality service” (SafetyCulture). Radii implements the Radii Way™, rigorously auditing every manufacturing partner.

Controls at every stage

Radii implements strict quality controls at every stage of the process, from quoting to delivery, ensuring each part meets the highest standards.

Tangible benefits

- Reduced rework: Automated manufacturability checks.

- Full traceability: Material certificates and CMM reports with every order.

- Transparency: Complete visibility into the part lifecycle.

Case study: from design to finished part in under two weeks

HP shortens its design cycle

HP, which holds a significant share of the printer market, worked with digital manufacturing platforms to drastically reduce its development timelines.

Protolabs helped reduce HP’s design cycle duration from the typical six to eight weeks down to just 15 days—or even less.

J. D. Hankins, an NPI engineer at HP, highlighted: “Being able to do everything online and get a quote within a few hours is incredible.”

BMW optimizes with AI

BMW Group has integrated AI into its manufacturing processes since 2019. One standout achievement: hundreds of thousands of synthetic images are generated with the push of a button, reducing by two-thirds the time employees need to deploy AI automation in quality control.

Radii in action

A Radii customer shared their experience: “They delivered urgent projects in two business days. The support, customer service, and product quality were incredible” (Radii).

These cases show that instant quoting isn’t just theory—leading companies are already seeing real benefits.

Conclusions and next steps

Instant quoting represents a paradigm shift in custom part manufacturing:

- Speed: From weeks to seconds.

- Accuracy: Automated DFM analysis that detects issues before production.

- Quality: Integration with ISO standards and rigorous audits.

- Nearshoring: Leverages Mexico’s strategic advantage.

Radii manages your entire supply chain, eliminating the need to coordinate multiple suppliers. With more than 200 manufacturing partners, access to more than 5,000 machines, and on-time delivery performance 2.5x above the average, Radii is the ideal partner for companies looking to scale without friction.

Do you have a project in mind? Upload your CAD file to Radii InstantQuote and get your quote in seconds.

Frequently Asked Questions

What is instant quoting?

Instant quoting is an automated process that calculates a part’s price and lead time from its CAD file, eliminating the traditional wait.

How does Radii InstantQuote work?

Radii InstantQuote works in three steps: CAD upload, automated DFM analysis, and price/lead time delivered in seconds—optimizing the quoting process.

What are the advantages of instant quoting over manual quoting?

Instant quoting reduces response time from weeks to seconds, enables faster design iteration, and improves competitiveness by accelerating time-to-market.

How does instant quoting impact the supply chain?

It transforms the supply chain by speeding up part purchasing, improving resilience, and leveraging nearshoring in Mexico for reduced transit times and competitive costs.

What quality benefits does Radii offer?

Radii ensures quality by integrating ISO 9001 standards and rigorous audits, ensuring each part meets the highest standards.

Sources

- https://www.radii.com.mx/en

- https://nvidia.com/es-la/case-studies/bmw-optimizes-production-with-ai-and-dgx-systems

- https://www2.deloitte.com/mx/es/pages/finance/articles/nearshoring-en-mexico-los-numeros-detras-del-relato.html

- https://bain.com/es/insights/mexico-en-una-encrucijada

- https://www.xometry.com/rapid-prototyping-service/

- https://safetyculture.com/es/listas-de-verificacion/formato-de-evaluacion-de-proveedores/

- https://extraflow.io/es/quoting-software/quoting-software-for-manufacturing

- https://www.rapiddirect.com/services/cnc-machining/

- https://www.mckinsey.com/locations/south-america/latam/hispanoamerica-en-potencia/la-geopolitica-y-la-geometria-del-comercio-global-actualizacion-2025/es-CL

- https://repositorio.buap.mx/rcontraloria/public/inf_public/2019/0/NOM_ISO_9001-2015.pdf

Have a project in mind?

Optimize cycle times and costs with our manufacturing network. Receive pricing and manufacturability validation in minutes.